News & events

In this section you will find all the latest news of the Danieli Group. Selecting the categories below, you can see News, Records, Start-ups, New Orders.

new technologies

2016, 1st February

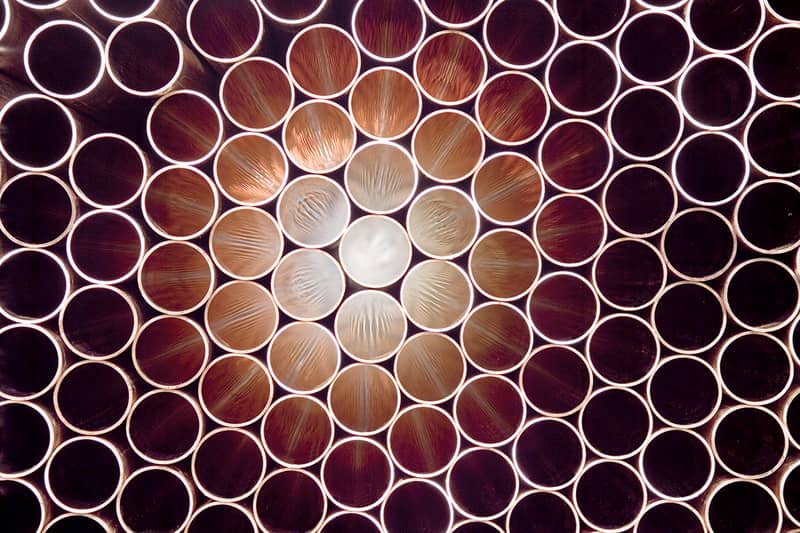

New Danieli Detection and Control Systems to improve copper tube eccentricity from 3 to 5%

A unique patented system specifically designed for chain track drawing process; applicable on existing and new plants

Tube eccentricity is an extremely critical control parameter for copper tubes since the greater the eccentricity of the tube, the greater the amount of copper material consumed during manufacturing. Because of the very high cost of the raw material (currently about 4,300 $/ton) an improvement in eccentricity of even only 1 or 2% can provide significant financial benefits (OPEX).

Danieli Centro Maskin, in cooperation with Danieli Automation, has reached a superior technological milestone in the development of a unique system to measure the eccentricity of the tube during production and correct it during the in-line drawing process. This goal is reached without reducing drawing speed. The entire straight length tube produced has a final eccentricity of 3 to 5%, resulting in material saving and consistent tube quality, with average tube eccentricity of 4%. Its super-compact design and high-precision operation makes it suitable for both new and existing plants as well as retrofitting existing Danieli plants and plants designed by other suppliers.

The DEC (Danieli Eccentricity Control) technology combined with the DED (Danieli Eccentricity Detection) system installed in the downstream processes, provide superb material eccentricity for real-time tube supply to obtain top quality control certification.