Minimills

a winning concept

and absolute market leadership

Evolution of Minimills

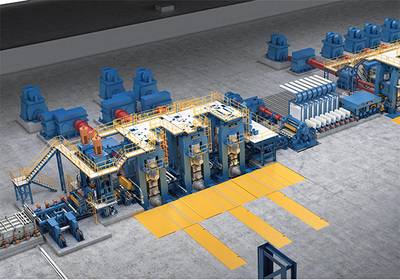

Electric Arc Furnace EAF-based steelmaking complexes that assure production flexibility, lean organizations, and low transportation costs for local raw-material sourcing and finished products distribution are the essence of the Minimill concept. At the beginning, this concept led to designs for plants with production capacities of 150-200,000 tpy, such as the first Minimill which was built by Danieli in Italy for Stefana group. Over the years, these designs gradually increased in production capability to over 2.9 Mtpy, especially when producing flat products. A significant step forward is represented by the “integrated Minimills” (DRI plants, EAFs, CCMs and rolling mills, all connected through a continuous energy-saving process, by a compact layout) that Danieli started supplying since 2006. This solution is particularly advantageous where scrap is not available and/or low-cost gas is available. In a future these plants might replace the highly capital intensive and less environmental friendly, traditional Blast Furnace integrated plants. Today, thanks to Danieli “Micromill” - a Minimill based on ultra-compact design and extremely low transformation costs - it is possible to produce 250-300,000 tpy of long products with an overall investment per ton typical of a 1.0-1.5 Mtpy Minimill. The relatively low output will assure additional savings in transportation costs, as these “regional mills” will transform local scrap into finished products for local markets.

The competitiveness of Danieli Minimills is ensured by:

> Energiron DRI modules (up to 250 tph, passivated DRI with variable carbon content and direct high-temp)

> EAFs with up to 40 heats/day

> 45 tph per strand bloom/billet casters

> Endless rolling for Flat and Long Products

> Bar production at speeds up to 50 m/sec into cooling bed

> “Spooler” bar in coil production up to 5 ton

> Free-size rolling concept for bars, wire rod and sections

> Ultra-long stackers for sections up to 36 m length

> Up to 2 Mtpy per strand thin slab casters

> Hot strip rolling down to 0.8 mm of thickness

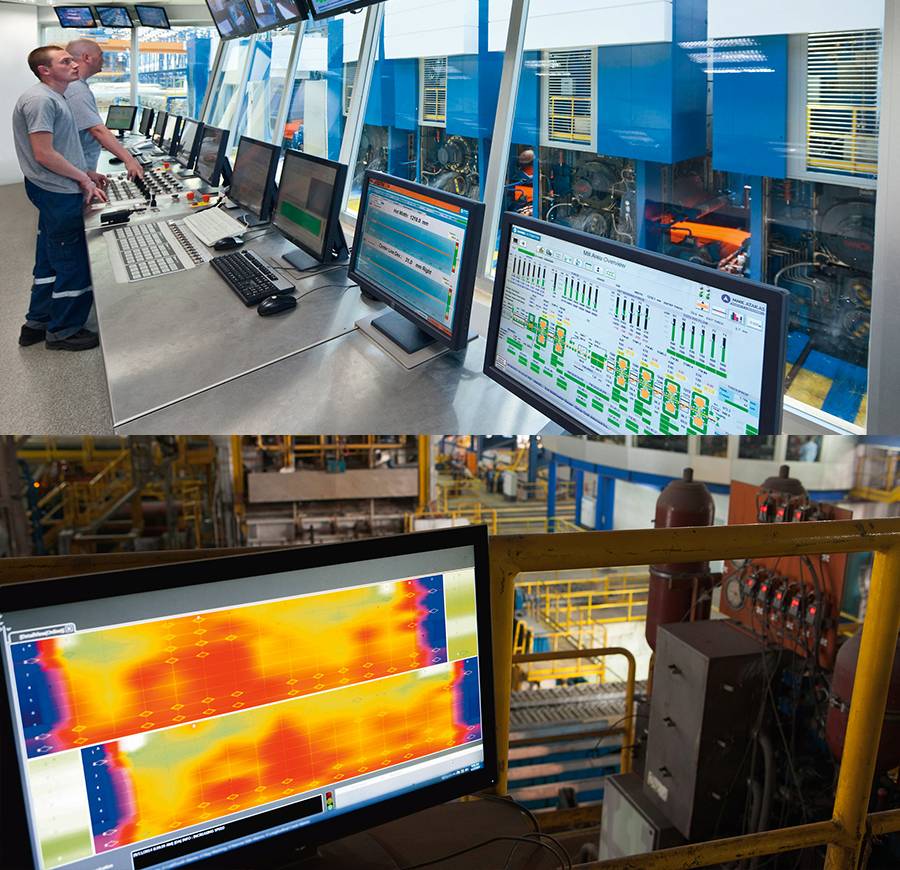

For the future we believe in the utmost production flexibility of 1.5 Mtpy combi-mills capable of producing both long and flat products in the widest variety of commercial steels. Danieli Minimills are supplied with fully integrated services, which include Turnkey supplies, auxiliary plants, process control automation, full service spectrum — all from a unique, single source of responsibility and management.

Around 85% of the Minimills operating worldwide today have been supplied by Danieli or operate with some Danieli equipment.

Type of Minimills

References for this products and technologies

Thanks to the technologies listed above, we contribute all or part of the production of the following plants.