CUSTOMER SERVICE

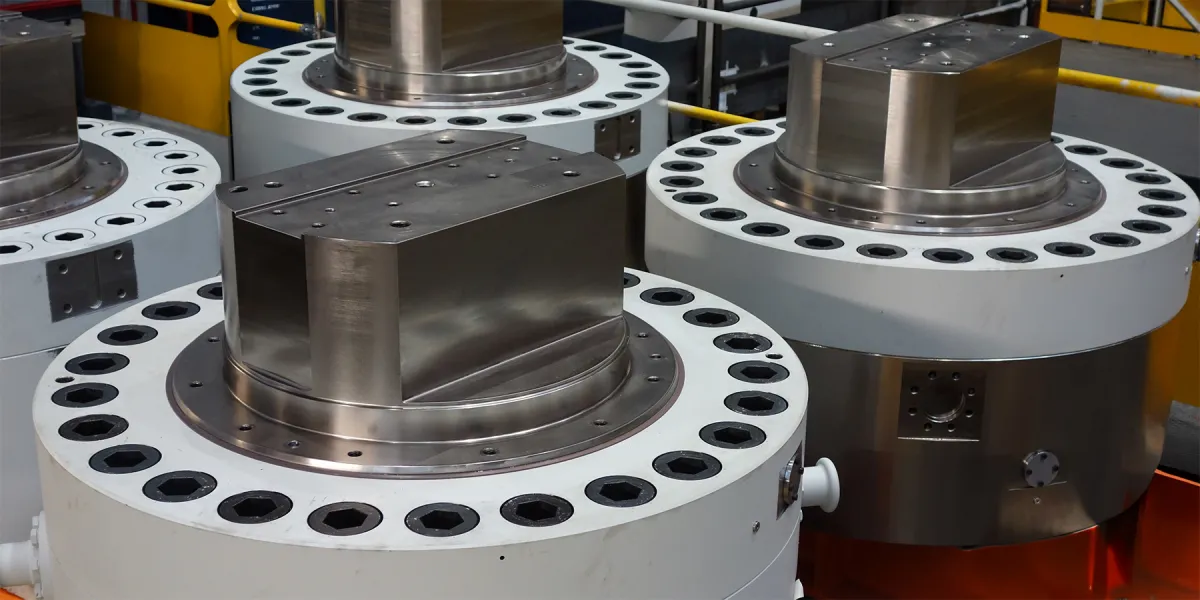

Hydraulic Automatic Gap Control cylinders

Danieli HAGC technology: the pioneer of precise and high-quality gauge control in rolling mills

Did you know the first ever Hydraulic Automatic Gauge Control was engineered and manufactured by Danieli? In a time when mill stand roll adjustments were made using the less precise screw-and-nut principle, we ushered-in a technological revolution by means of digitally controlled hydraulic systems which would redefine the capabilities and ease of use of rolling mills across the world.

This equipment is one telling example of Danieli’s culture of continuous product quality improvement through relentless Research and Development, innovation and digitalization.

Danieli HAGC technology provides precise and accurate control over the thickness of the steel being rolled. Starting a rolling mill campaign with a reliable baseline, continuously monitoring the thickness of the steel and adjusting the position of the work rolls in real-time with extremely high accuracy, our HAGC systems ensures that the steel is rolled to the required dimensional tolerances. This is important because it ensures that the finished steel products meet the required specifications and quality standards.

The automatic feedback loop of Danieli HAGCs plays a key role in improving the efficiency of the rolling process: autonomously adjusting the position of the work rolls, HAGCs help minimize the number of passes required to achieve the desired thickness of the steel. This can help reduce the overall rolling time and increase the productivity of the rolling mill.

The key characteristics of Danieli’s HAGC system in steel rolling mills are precision, fast response time, high reliability, wide control range, and compatibility with a wide range of rolling mill equipment and control systems. Especially important for our clients is the fast response of micro-corrections in thickness control and in roll position adjustment, which provides the flexibility to obtain premium quality output even when, for example, the mill stand structure is stretched, or the rolls manifest an eccentricity defect.

The importance of these features and advantages cannot be overstated: this critical Danieli equipment helps our clients achieve the best possible performance in their rolling mill stands and represents the key in obtaining a higher quality and thinner strip coils in a uniform manner.